With the continuous development and introduction of the plastic extrusion industry in foreign manufacturing and processing, LEZ has adjusted and upgraded the business and service scope of overseas manufacturers engaged in plastic extrusion processing.

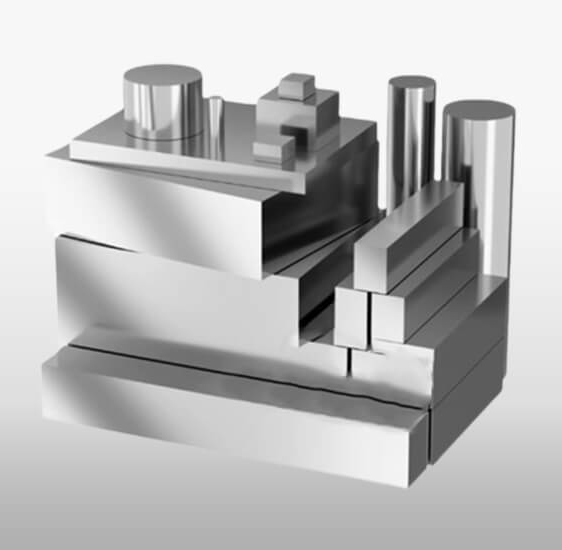

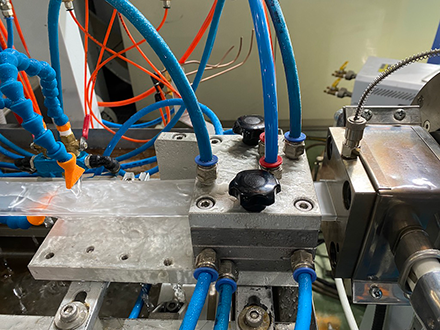

Relying on the company's 20 years of experience in plastic extrusion production and mold manufacturing, we provide foreign plastic extrusion industry and factories with (profile molds and pipe molds) design and mold making, as well as providing mold testing services and technical advice and technical support.

Experiences

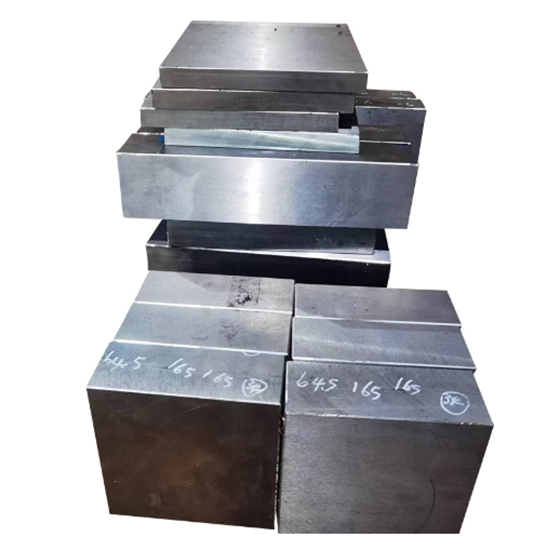

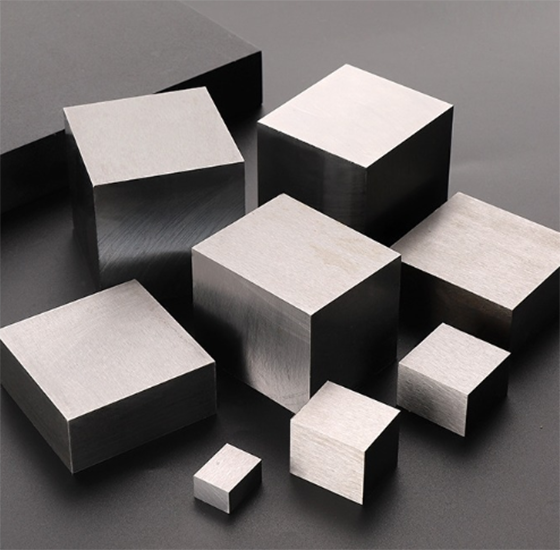

When you choose the correct tool steel for your plastic extrusion molding project, you can make an informed choice by familiarizing yourself with the specific features of all types of extrusion mold steel. To help you choose the best option for your product, you should speak with LEZ.

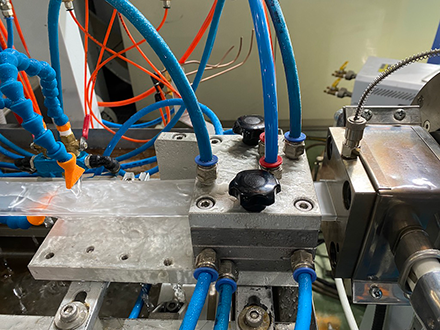

Strength factory with many fine equipments strength factory with many fine equipments.

Customized mold design.

Perfect quality management system.

Senior engineers with more than 10 years experience.

One-stop service from design to molding.

Get a Free Quote