Therefore, the big question is that how tube is extensively used in different jobs or activities? Familiarizing yourself with the various types of plastic tubing allows you to select the appropriate tubing for your respective application.

Types of Plastic Tubes:

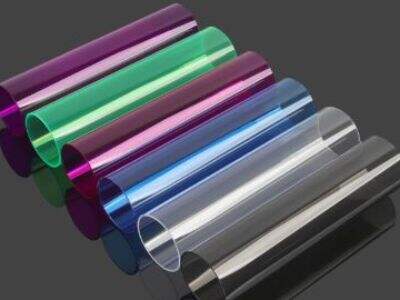

There are tons of various plastic tubes such as PVC, polycarbonate, and acrylic. They all have unique features that make them suitable for specific tasks. Consider how each type will fit your needs.

PVC "-grade" tubes are tough, resists chemicals, and have many applications in plumbing and construction.

They are tough polycarbonate tubes that can absorb heavy impact. They can be found in things like safety barriers and machine covers.

Acrylic tubes are lightweight and transparent, suitable for display cases and lights.

How To Choose Plastic Tubes: Considerations

Plastic, for example, when selecting plastic tubes for the job, consider a few things. Test the tube for heat tolerance, chemical resistance, and tensile strength. This will ensure that it will function properly within your environment.

Also take a look at the tube width and the tube thickness. This will ensure that it holds up well under pressure and stress in its job. Even the finish and color of the tube matters, them affect how they will look and feel.

Where to Find the Right Size and Shape:

The size and shape of the plastic tubes is where finding the right fit is crucial for ensuring that they are able to deliver on the job. Measure carefully to discover what length, width, and thickness the tube needs.

Sometimes you need those special features: extra parts or bends to fit your requirements. You also have a natural instinct towards the weight, and versatility of the tube, as these can make a tubing process much easier or much more difficult.

Testing the Strength and Operability of the Tubes:

When considering Extruded Plastic Profiles, always test the strength and functionality. Check things like its sun resistance, impact resistance, and heat resistance. This would help you choose tubes with great longevity.

You have to test them and what conditions work best. You want tubes that are strong and durable so you do not spend extra on repairs.

Tubes: Tailoring Equipment for Your Requirements

Consider personalized plastic tubes if you require anything unique for your project. The tubes can be customized in size, shape, material, and color by many makers, just for you.

For instance,Plastic Packaging Tubes it is possible to use customization to add features to the tubes, such as textures or special designs, to help them function better. You might also have options to choose different colors and finishes in order to make it your own.

In a way of concondation, things to consider when ordering plastic tubes include both type of plastic tube, factors and tips affecting them, strength and performance checks. This doesn't mean you have to launch right away; by researching these factors ahead of time, you're able to select the tubes that are most suited to you,Extruded Plastic Tubes which will guarantee that your project will be carried out successfully. If you have any doubts, you can always consult an expert to help you choose the best plastic tubes for you.